Talk to us

08071930525

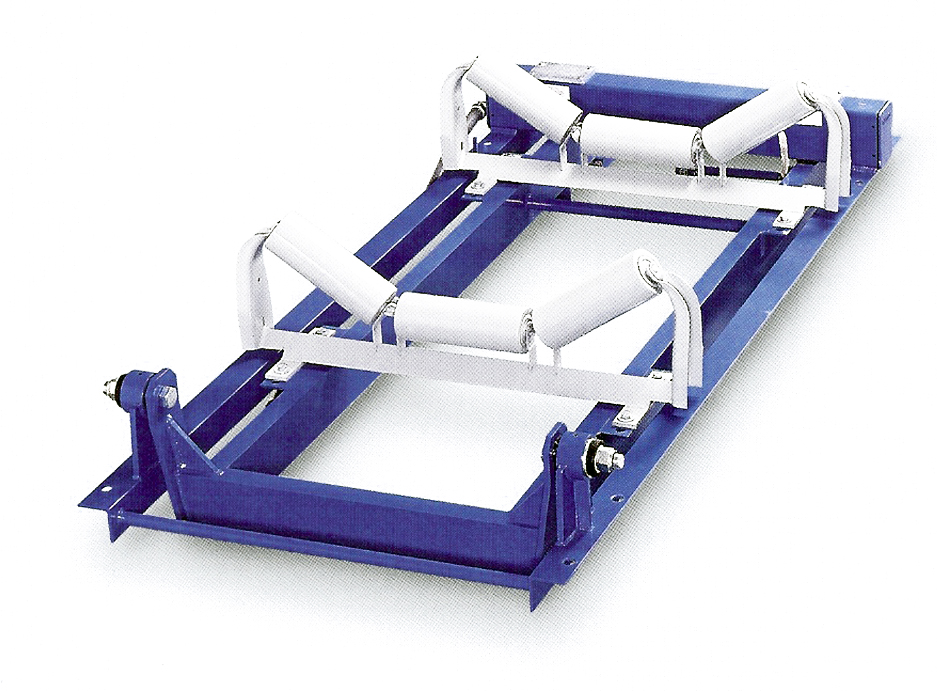

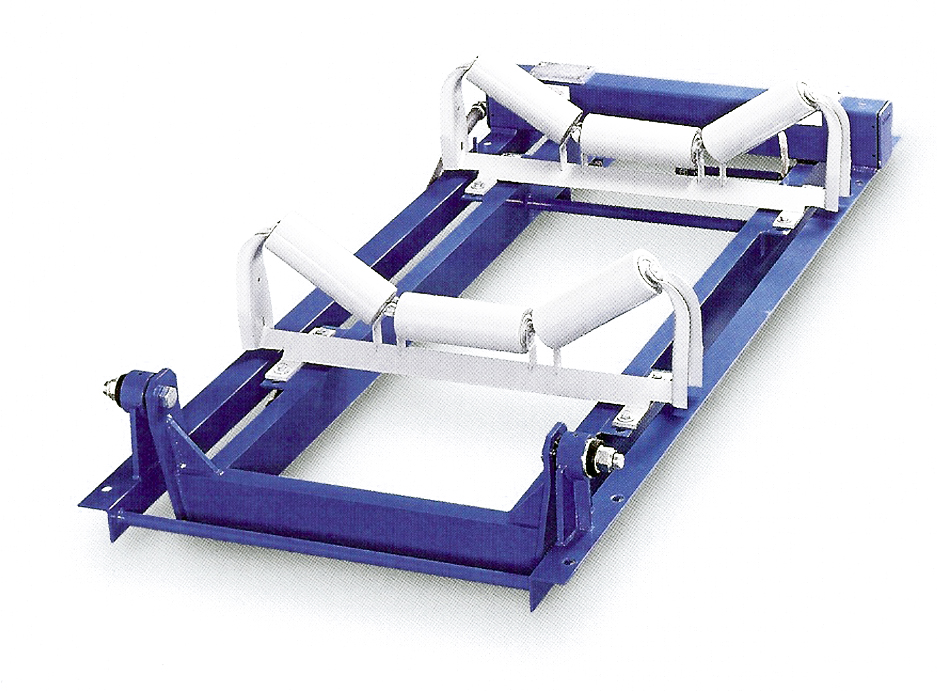

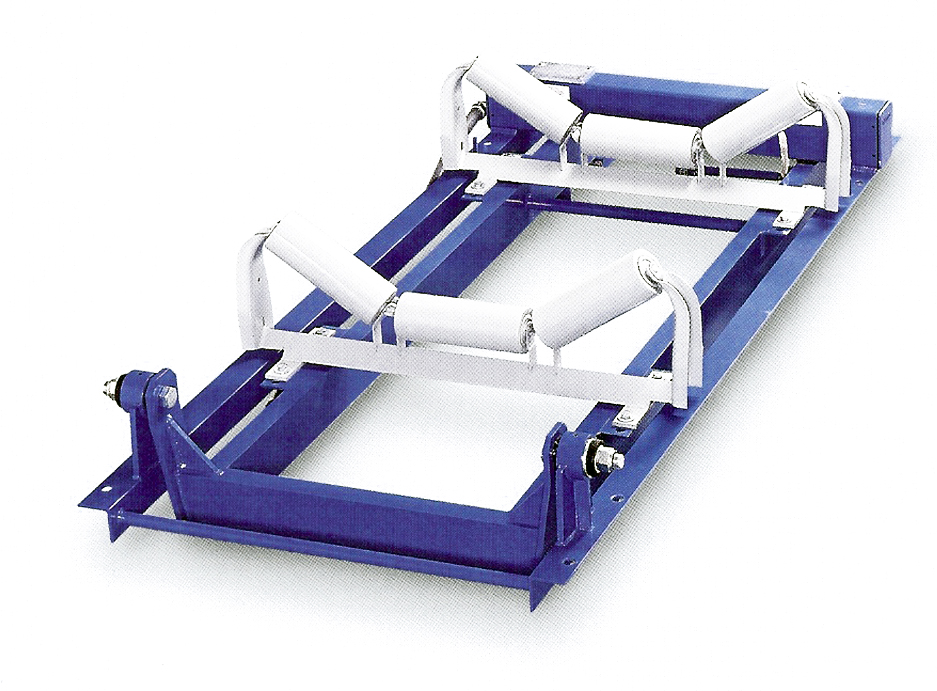

A Belt Weigheralso known as a belt scale, conveyor scale, or weigh belt systemis an inline weighing device used to measure the mass flow rate of bulk materials transported on a conveyor belt. It provides continuous, real-time weight data essential for process control, inventory management, and production monitoring.

A belt weigher is designed to:

Measure the instantaneous flow rate (e.g., tons/hour)

Record totalized material throughput (e.g., tons/day or tons/shift)

Maintain accuracy during continuous operation

Enable automated process control, such as feeding, batching, blending, and loadout operations

It achieves this by combining a load cell system with a speed sensor to calculate material mass per unit length and total flow.

Measure the weight of material on a section of the conveyor.

High-precision, temperature-compensated sensors ensure accuracy.

Specially designed idlers support the belt in a way that isolates and transfers material weight to the load cells.

Detects conveyor belt speed via rollers or a shaft encoder.

Calculates:

Mass flow rate (t/h)

Total material conveyed

Belt speed

Provides local display and communication to PLC/SCADA systems.

Includes test weights or electronic calibration options for accuracy verification.

Material passes over the weigh frame on the conveyor.

Load cells detect the weight of material per unit length of belt.

The speed sensor measures belt velocity.

The controller multiplies:

Load per meterBelt speed=Mass flow rate\text{Load per meter} \times \text{Belt speed} = \text{Mass flow rate}Total mass is integrated over time.

High accuracy (0.25% to 1% depending on model)

Rugged, industrial construction

Compatible with multiple conveyor widths and speeds

Real-time digital display

Multiple communication protocols (Modbus, Profibus, Ethernet/IP)

Automatic zero tracking and calibration functions

Integrated diagnostics and alarms

Belt weighers are widely used in industries such as:

Mining & Quarrying (coal, ores, aggregates)

Cement & Building Materials

Agriculture (grain, fertilizer)

Power Generation (coal handling)

Chemical & Petrochemical

Food Processing (sugar, salt, grains)

Recycling & Waste Management

Accurate production monitoring

Reduced material losses

Improved process control

Automated inventory management

Operational efficiency and cost savings

Compliance with reporting and quality standards

Price:

Minimum Order Quantity : 1 Unit

Warranty : Yes

Product Type : Filling System

Material : Steel

Minimum Order Quantity : 10 Units

Warranty : Yes

Product Type : Weighing System

Material : Steel

Power Supply : Electricity

Minimum Order Quantity : 10 Units

Warranty : Yes

Product Type : Weighing System

Material : Steel

Power Supply : Electricity