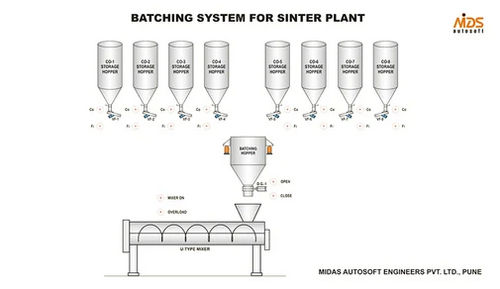

About Sinter Plant Batching System

Unlock peerless efficiency and enviable mixing accuracy with the SPBS-6000 Sinter Plant Batching Systema must-have for modern industrial batching demands. Avail this hot deal at a special rate and elevate your production line! Engineered for batchwise, programmable operations with multiple hoppers, it promises 1% precision. The integrated dust extraction system, PLC-controlled automation, electric drive, and touchscreen HMI ensure potent performance and effortless operation. Compliant with ISO 9001 standards and featuring easy access panels and readily available replacement parts, this system is your ideal choice for reliable, high-capacity batching.

Optimized Batching for Sinter Plants

The SPBS-6000 stands out in sinter plant raw material batching, delivering exceptional uniformity and accuracy. Designed for use in industrial settings, this system adapts seamlessly to varying ambient conditions and site requirements. Key features include integrated dust control, advanced PLC automation, and extensive batch report storage. Its versatile design accommodates multiple hoppers and customizable production capacities, making it indispensable for steel and metal manufacturing plants needing robust, accurate batching with effortless operation and maintenance.

Shipping, Packaging, and Policy Details

Estimate timely shipment through our trusted FOB India port, ensuring efficient supply to your site. Each unit is delivered with a comprehensive assembly and maintenance manual, properly packaged to safeguard components during transit. Our sample policy supports evaluation before full-scale orders, reflecting our commitment to customer satisfaction. With reliable supply and meticulous shipment processes, you can expect your SPBS-6000 batching system to arrive securely and ready for installation.

FAQs of Sinter Plant Batching System:

Q: How accurate is the mixing process of the SPBS-6000 Sinter Plant Batching System?

A: The SPBS-6000 offers an impressive mixing accuracy of 1%, ensuring precise batch composition every time.

Q: What is the primary usage of this batching system?

A: This system is primarily used in sinter plant raw material batching processes for steel and metal manufacturing industries.

Q: When are replacement parts available for the SPBS-6000?

A: Replacement parts are readily available, allowing for quick maintenance and minimal downtime during operations.

Q: Where can the SPBS-6000 be efficiently installed?

A: It can be efficiently installed at industrial sites, including sinter plants and raw material handling facilities, accommodating up to 95% relative humidity and various ambient conditions.

Q: What makes the operation of this machine user-friendly?

A: The SPBS-6000 features a touchscreen HMI, programmable batchwise operation, and easy front access panels, simplifying daily operation and routine maintenance.